60227 IEC 53(RVV)

Rated temperature (°C): 70°C

Withstand voltage: 2000V

Reference standard: GB/T 5023.5-2008/IEC 60227-5:2003

Keyword: 60227 IEC 53(RVV)

Category:

CCC certification

Product Introduction

| Specifications |

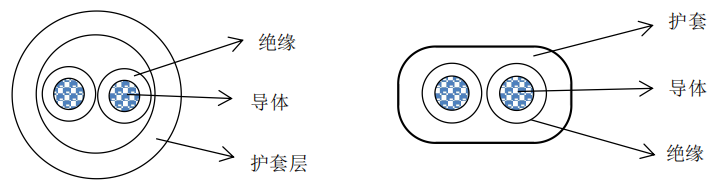

60227 IEC 53(RVV) 2C×(0.75~2.5mm 2 ) | ||||||

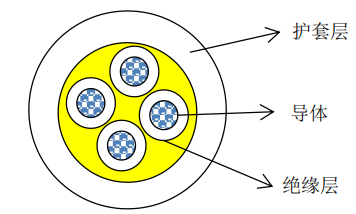

| Cross-sectional diagram |

|

||||||

| Marking content | CCC A164579 60227 IEC 53(RVV) 300/500V n×***mm 2 Lianyang Cable (Meter Mark) (Note: n represents the number of cores, *** represents the wire gauge) | ||||||

| Rated voltage (V) |

300V/500V |

Withstand voltage |

2000V |

||||

| Rated temperature (°C) |

70 |

Reference standard |

GB/T 5023.5-2008/IEC 60227-5:2003 | ||||

| Physical properties | Insulation (before aging) | Tensile strength: ≥10.0N/mm 2 | Minimum elongation at break: 150% | ||||

| Sheath (before aging) | Tensile strength: ≥10.0N/mm 2 | Minimum elongation at break: 150% | |||||

| Aging conditions | 80±2℃*168h in air oven | ||||||

| Insulation (after aging) | Tensile strength: change rate ±20% | Minimum elongation at break: change rate ±20% | |||||

| Sheath (after aging) | Tensile strength: change rate ±20% | Minimum elongation at break: change rate ±20% | |||||

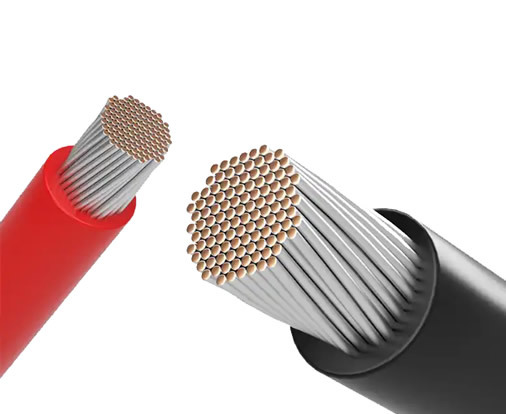

| Conductor material | Bare copper wire | Insulation/sheath material | PVC | ||||

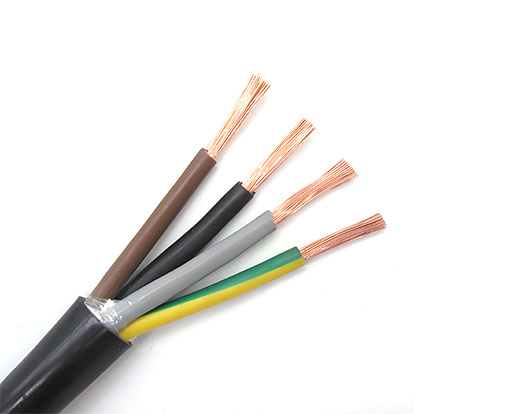

| Insulated core color | Brown, Blue | Sheath color | Commonly used black sheath | ||||

| Remarks | Colors can be customized according to needs; the standard sheath is black. | ||||||

| Structure Technical Parameters/Construction | |||||||

| Serial number | Number of cores * Nominal cross-sectional area mm 2) |

Conductor structure (Number of strands/Conductor diameter mm±0.008) |

Average insulation thickness (≧mm) |

Finished core outer diameter (mm) |

Average sheath thickness (≧mm) |

Finished outer diameter (mm) |

Maximum conductor resistance at 20℃ (Ω/km) |

| 1 | 2x0.75 | 24/0.195 | 0.6 | 2.35±0.15 | 0.8 | 6.3±0.3 | 26.0 |

| 2 | 2x0.75 | 24/0.195 | 0.6 | 2.35±0.15 | 0.8 | 4.1x6.5±0.3 | 26.0 |

| 3 | 2x1.0 | 32/0.195 | 0.6 | 2.55±0.15 | 0.8 | 6.8±0.3 | 19.5 |

| 4 | 2x1.0 | 32/0.195 | 0.6 | 2.50±0.15 | 0.8 | 4.3x6.9±0.3 | 19.5 |

| 5 | 2x1.5 | 48/0.195 | 0.7 | 3.00±0.15 | 0.8 | 7.6±0.4 | 13.3 |

| 6 | 2x1.5 | 50/0.245 | 0.8 | 3.60±0.15 | 1.0 | 9.3±0.5 | 7.98 |

| Specifications |

60227 IEC 53(RVV) 3C×(0.75~2.5mm 2 ) | ||||||

| Cross-sectional diagram |

|

||||||

| Marking content | CCC A164579 60227 IEC 53(RVV) 300/500V n×***mm 2 Lianyang Cable (Meter Mark) (Note: n represents the number of cores, *** represents the wire gauge) | ||||||

| Rated voltage (V) |

300V/500V |

Withstand voltage |

2000V |

||||

| Rated temperature (°C) |

70 |

Reference standard |

GB/T 5023.5-2008/IEC 60227-5:2003 | ||||

| Physical properties | Insulation (before aging) | Tensile strength: ≥10.0N/mm 2 | Minimum elongation at break: 150% | ||||

| Sheath (before aging) | Tensile strength: ≥10.0N/mm 2 | Minimum elongation at break: 150% | |||||

| Aging conditions | 80±2℃*168h in air oven | ||||||

| Insulation (after aging) | Tensile strength: change rate ±20% | Minimum elongation at break: change rate ±20% | |||||

| Sheath (after aging) | Tensile strength: change rate ±20% | Minimum elongation at break: change rate ±20% | |||||

| Conductor material | Bare copper wire | Insulation/sheath material | PVC | ||||

| Insulated core color | Brown, Blue, Yellow/Green | Sheath color | Commonly used black sheath | ||||

| Remarks | Colors can be customized according to needs; the standard sheath is black. | ||||||

| Structure Technical Parameters/Construction | |||||||

| Serial number | Number of cores * Nominal cross-sectional area mm 2) |

Conductor structure (Number of strands/Conductor diameter mm±0.008) |

Average insulation thickness (≧mm) |

Finished core outer diameter (mm) |

Average sheath thickness (≧mm) |

Finished outer diameter (mm) |

Maximum conductor resistance at 20℃ (Ω/km) |

| 1 | 3x0.75 | 24/0.195 | 0.6 | 2.35±0.15 | 0.8 | 6.8±0.3 | 26.0 |

| 2 | 3x1.0 | 32/0.195 | 0.6 | 2.55±0.15 | 0.8 | 7.2±0.3 | 19.5 |

| 3 | 3x1.5 | 48/0.195 | 0.7 | 3.00±0.15 | 0.9 | 8.4±0.3 | 13.3 |

| 4 | 3x2.5 | 50/0.195 | 0.8 | 3.60±0.15 | 1.1 | 10.1±0.3 | 7.98 |

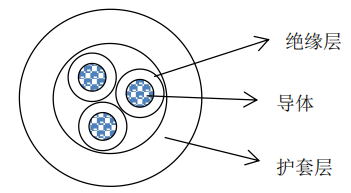

| Specifications |

60227 IEC 53(RVV) 4C×(0.75~2.5mm 2 ) | ||||||

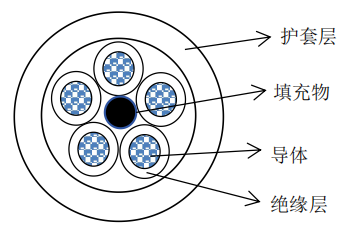

| Cross-sectional diagram |

|

||||||

| Marking content | CCC A164579 60227 IEC 53(RVV) 300/500V n×***mm 2 Lianyang Cable (Meter Mark) (Note: n represents the number of cores, *** represents the wire gauge) | ||||||

| Rated voltage (V) |

300V/500V |

Withstand voltage |

2000V |

||||

| Rated temperature (°C) |

70 |

Reference standard |

GB/T 5023.5-2008/IEC 60227-5:2003 | ||||

| Physical properties | Insulation (before aging) | Tensile strength: ≥10.0N/mm 2 | Minimum elongation at break: 150% | ||||

| Sheath (before aging) | Tensile strength: ≥10.0N/mm 2 | Minimum elongation at break: 150% | |||||

| Aging conditions | 80±2℃*168h in air oven | ||||||

| Insulation (after aging) | Tensile strength: change rate ±20% | Minimum elongation at break: change rate ±20% | |||||

| Sheath (after aging) | Tensile strength: change rate ±20% | Minimum elongation at break: change rate ±20% | |||||

| Conductor material | Bare copper wire | Insulation/sheath material | PVC | ||||

| Insulated core color | Brown, Black, Gray, Yellow/Green | Sheath color | Commonly used black sheath | ||||

| Remarks | Colors can be customized according to needs; the standard sheath is black. | ||||||

| Structure Technical Parameters/Construction | |||||||

| Serial number | Number of cores * Nominal cross-sectional area mm 2) |

Conductor structure (Number of strands/Conductor diameter mm±0.008) |

Average insulation thickness (≧mm) |

Finished core outer diameter (mm) |

Average sheath thickness (≧mm) |

Finished outer diameter (mm) |

Maximum conductor resistance at 20℃ (Ω/km) |

| 1 | 4x0.75 | 24/0.195 | 0.6 | 2.35±0.15 | 0.8 | 7.3±0.3 | 26.0 |

| 2 | 4x1.0 | 32/0.195 | 0.6 | 2.55±0.15 | 0.9 | 8.0±0.3 | 19.5 |

| 3 | 4x1.5 | 48/0.195 | 0.7 | 3.00±0.15 | 1.0 | 9.3±0.3 | 13.3 |

| 4 | 4x2.5 | 50/0.245 | 0.8 | 3.60±0.15 | 1.1 | 10.9±0.3 | 7.98 |

| Specifications |

60227 IEC 53(RVV) 5C×(0.75~2.5mm 2 ) | ||||||

| Cross-sectional diagram |

|

||||||

| Marking content | CCC A164579 60227 IEC 53(RVV) 300/500V n×***mm 2 Lianyang Cable (Meter Mark) (Note: n represents the number of cores, *** represents the wire gauge) | ||||||

| Rated voltage (V) |

300V/500V |

Withstand voltage |

2000V |

||||

| Rated temperature (°C) |

70 |

Reference standard |

GB/T 5023.5-2008/IEC 60227-5:2003 | ||||

| Physical properties | Insulation (before aging) | Tensile strength: ≥10.0N/mm 2 | Minimum elongation at break: 150% | ||||

| Sheath (before aging) | Tensile strength: ≥10.0N/mm 2 | Minimum elongation at break: 150% | |||||

| Aging conditions | 80±2℃*168h in air oven | ||||||

| Insulation (after aging) | Tensile strength: change rate ±20% | Minimum elongation at break: change rate ±20% | |||||

| Sheath (after aging) | Tensile strength: change rate ±20% | Minimum elongation at break: change rate ±20% | |||||

| Conductor material | Bare copper wire | Insulation/sheath material | PVC | ||||

| Insulated core color | Brown, Black, Gray, Yellow/Green | Sheath color | Commonly used black sheath | ||||

| Remarks | Colors can be customized according to needs; the standard sheath is black. | ||||||

| Structure Technical Parameters/Construction | |||||||

| Serial number | Number of cores * Nominal cross-sectional area mm 2) |

Conductor structure (Number of strands/Conductor diameter mm±0.008) |

Average insulation thickness (≧mm) |

Finished core outer diameter (mm) |

Average sheath thickness (≧mm) |

Finished outer diameter (mm) |

Maximum conductor resistance at 20℃ (Ω/km) |

| 1 | 5x0.75 | 24/0.195 | 0.6 | 2.35±0.15 | 0.9 | 8.2±0.3 | 26.0 |

| 2 | 5x1.0 | 32/0.195 | 0.6 | 2.55±0.15 | 0.9 | 8.7±0.3 | 19.5 |

| 3 | 5x1.5 | 48/0.195 | 0.7 | 3.00±0.15 | 1.1 | 10.3±0.3 | 13.3 |

| 4 | 5x2.5 | 50/0.245 | 0.8 | 3.60±0.15 | 1.2 | 12.2±0.3 | 7.98 |

Related Products

Photovoltaic cable

As a key component of photovoltaic power generation, Lianyang has specially developed cables for photovoltaic inverters, such as UL10269, UL11627, UL3271, and UL1032. They feature a soft structure, good insulation and flame retardant properties, and optional temperature ratings of -40° ~ 125°, and voltage ratings of 300V~2000V. They can be used in harsh environments such as high altitude, high temperature, high cold, and high salt spray, suitable for photovoltaic power generation installations in various environments.

Learn MoreEnergy storage cable

Energy storage cables are mainly used in the battery interconnections, connections between batteries and inverters, and BMS connections in fields such as mobile energy storage power stations, energy storage demonstration power stations, wind power energy storage systems, and peak-shaving energy storage systems. The rated voltage is DC1500V and below: the highest temperature rating is 150℃. The use environment requires the cable to have the properties of being soft, having a long service life, being resistant to high and low temperatures, being resistant to chemical reagents, being resistant to battery acid, and being highly flame-retardant. For cables used outdoors for long periods, sunlight aging tests are conducted, and salt spray tests are added for cables near the sea or in high-temperature and high-humidity environments to ensure the reliability of the battery connection cables used in energy storage systems.

Learn MoreElectric vehicle charging cable

The product is soft, with a good feel, and has a bending radius of less than 5D; it is oil-resistant, acid- and alkali-resistant, water-resistant, wear-resistant, tensile-resistant, crush-resistant, crack-resistant, UV-resistant, and colorfast; it has good flame retardant properties; and it is bend-resistant. It is mainly used to connect electric vehicle charging devices with charging infrastructure to transmit electricity to electric vehicles, and is equipped with a certain number of signal lines, control lines, and auxiliary power lines to ensure accurate control and safe operation of the entire charging process.

Learn MoreIndustrial air conditioning cable

Industrial cables include single-core wires and cables, silicone rubber cables, shielded control cables, flame-retardant cables, fire-resistant cables, etc. They are mainly used for power supply and equipment control within electrical boxes in fields such as CNC machine tools, woodworking machinery, textile machinery, injection molding machinery, battery manufacturing machinery, robot integrated systems, industrial automation equipment, industrial ovens, factory and smart building air conditioning equipment, HVAC equipment, and office automation. They are used for fixed, vibrating, and occasionally mobile cable laying.

Learn More

No. 18, Xincheng Avenue, Lianyang Industrial Park, Huizhou Industrial Transfer Industrial Park, Longmen County, Huizhou City

WeChat Consultation

Copyright © Huizhou Lianyang Cable Technology Co., Ltd. All rights reserved.